Chemical process pumps: an indispensable force in fine processes

2024-01-22In today's chemical industry, chemical process pumps are gradually becoming an indispensable and important component in the production process. These advanced pump technologies are providing chemical companies with more efficient and reliable fluid handling solutions, empowering various precision processes, and becoming an innovative force that attracts attention in the industry.

What is a chemical process pump?

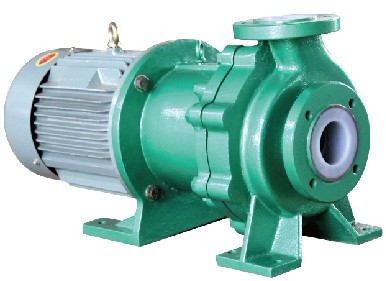

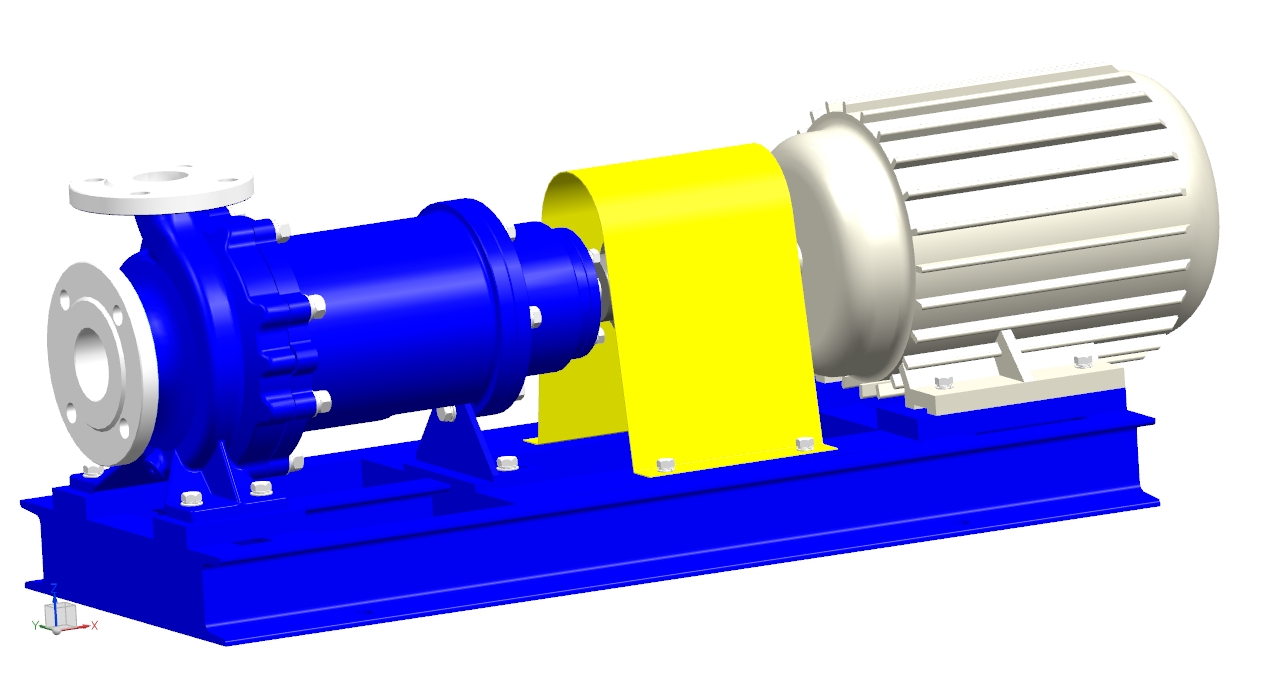

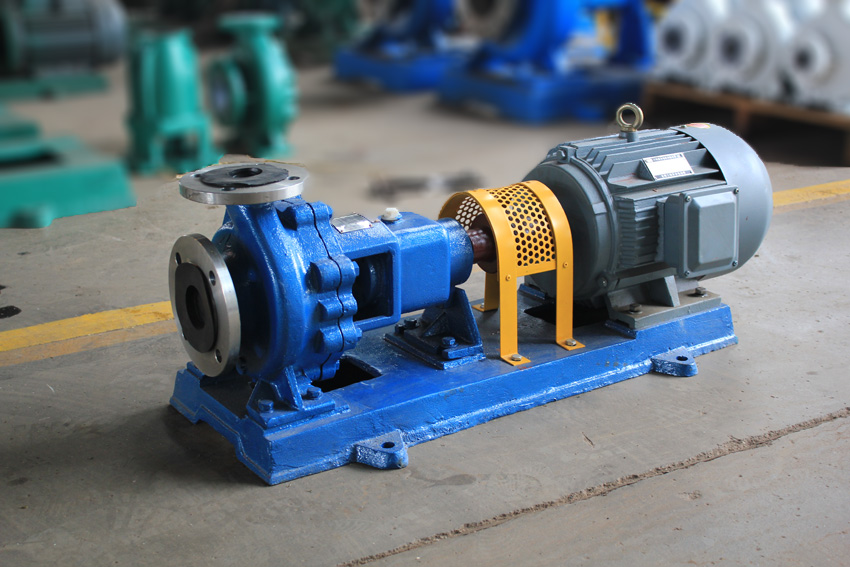

Chemical process pumps are pumps specially designed to handle various corrosive, high temperature and high pressure, toxic and harmful chemical media. Compared with traditional pumps, chemical process pumps are specially optimized in terms of material selection, sealing performance, corrosion resistance, etc. to adapt to the extremely challenging fluid handling environment in the chemical industry.

1. The importance of material selection

One of the core features of chemical process pumps is their choice of materials. Since highly corrosive media are often involved in chemical production, these pumps usually use high-performance corrosion-resistant materials such as plastics, ceramics, stainless steel, etc. to ensure excellent durability in extreme environments.

2. Multifunctional design adapted to complex processes

Chemical process pumps are more than just tools for transporting chemical media, they are also designed with multi-functional needs in different delicate processes in mind. These pumps may need to adjust flow, change pressure, and adapt to different temperatures, so they are often highly adjustable to accommodate complex and changing production processes.

3. Enhancement of sealing performance

When dealing with chemical media, the sealing performance of the pump is particularly critical. Chemical process pumps are usually equipped with a highly sealed design to prevent leakage and external contamination, ensuring the safety and environmental protection of the production process.

4. Wide range of applications

Chemical process pumps have a wide range of applications in the chemical industry. They can be used to transport acid and alkali solutions, handle corrosive liquids, and even perform high-temperature and high-pressure reactions under special conditions. These pumps play an irreplaceable role in chemical production, pharmaceuticals, food industry and other fields.

5. Innovation drives industry development

As the chemical industry continues to develop, the demand for chemical process pumps is gradually increasing. Pump manufacturers continue to innovate to improve product performance and reliability to meet industry demands for higher standards. Advanced technology and intelligent control systems are becoming a new trend in chemical process pumps, further promoting the development of the entire industry.

6. Industry compliance and sustainable development

In the chemical industry, compliance and sustainability are increasingly important keywords. The design and manufacture of chemical process pumps need to comply with strict industry standards and regulations to ensure the highest safety and environmental standards during the production process and promote the sustainable development of the entire industry.

As technology continues to advance and industry needs expand, chemical process pumps will continue to play a vital role. Its advantages in improving production efficiency, ensuring production safety, and ensuring environmental compliance will inject new vitality into the chemical industry and promote the continuous innovation and development of the industry.