Revolutionizing Pump Technology: Unveiling the Fluorine-Lined Pump for Enhanced Performance

2024-01-15With the continuous advancement of technology, all walks of life are constantly seeking innovative solutions to improve the efficiency and reliability of industrial processes. During this wave, a technology called "Fluorine lined pump" emerged, which has attracted much attention for its excellent chemical inertness and corrosion resistance.

What is Fluorine lined pump?

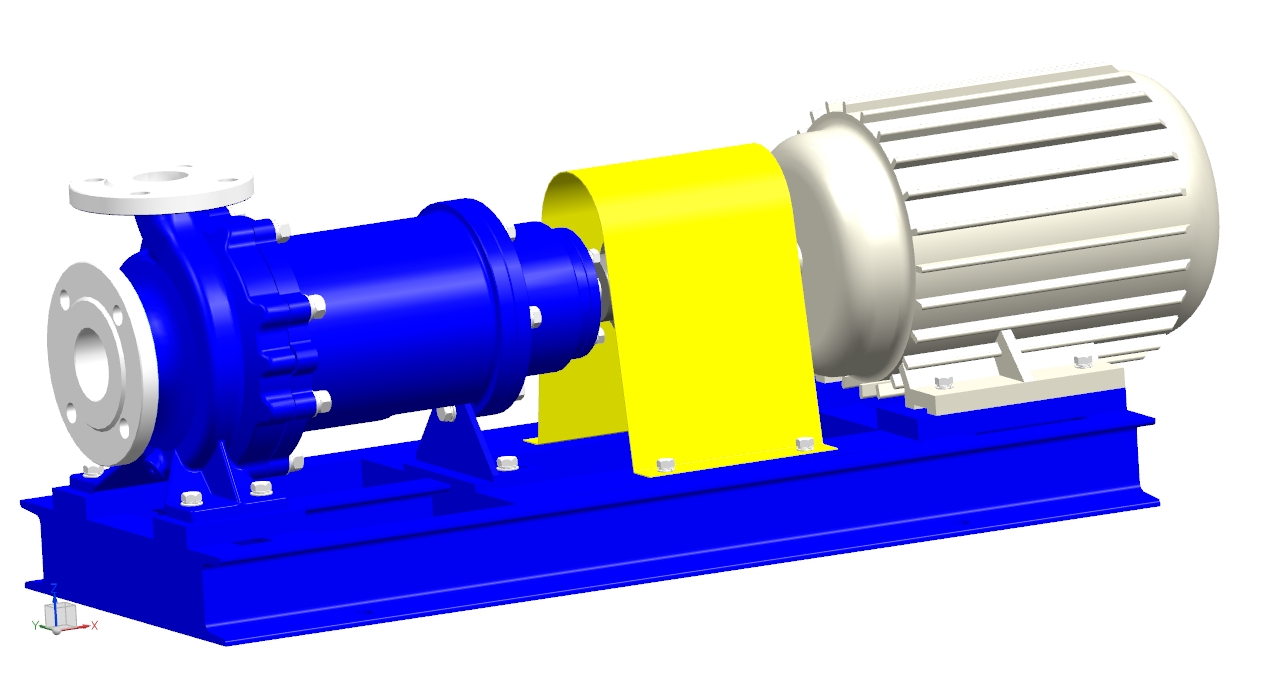

A fluorine lined pump is a type of pump that has a lining made of fluorine-based materials on the internal surfaces that come into contact with the pumped fluid. This lining is typically made of materials such as PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy) , which are known for their excellent chemical resistance and low friction properties.

The fluorine lining in these pumps provides protection against corrosive and abrasive fluids, making them suitable for handling a wide range of aggressive chemicals and acids. It helps prevent the pump from being damaged or degraded by the chemicals it is pumping. Additionally, the low friction properties of the fluorine lining minimize the wear and tear on the pump, improving its overall efficiency and lifespan.

Fluorine lined pumps are commonly used in industries such as chemical processing, pharmaceuticals, wastewater treatment, and mining, where there is a need for reliable and durable pumps to handle corrosive fluids. They offer a cost-effective solution for safely and efficiently transferring chemicals while ensuring the longevity of the pump.

Basic principles of Fluorine lined pump

A fluorine lined pump is a pump that is lined with a fluoropolymer (usually polytetrafluoroethylene, PTFE) on the internal surface of the pump. This special design was inspired by a deep understanding of the challenges conventional pumps encounter when handling corrosive liquids. By introducing a fluoropolymer lining to the internal surface of the pump, the Fluorine lined pump has achieved a significant breakthrough in corrosion resistance and chemical stability.

Advantages of Fluorine lined pump

1. Excellent corrosion resistance: Fluoropolymers are known for their excellent chemical inertness and can resist the erosion of various strong acids, strong alkalis and other corrosive substances. Therefore, Fluorine lined pumps are ideal for handling corrosive liquids.

2. Chemical stability: Fluorine lined pump not only performs well in corrosive environments, but also remains stable under extreme temperature conditions. This makes it widely applicable in some extreme industrial environments, such as chemical, pharmaceutical and electronic industries.

3. Reduce the risk of leakage: Due to the extremely low surface energy of fluoropolymer, Fluorine lined pump can reduce the adhesion of liquid in the pump and reduce the risk of leakage. This is essential to improve the security and reliability of the system.

4. Wear resistance: Fluoropolymer exhibits excellent wear resistance, extending the service life of the Fluorine lined pump and reducing maintenance costs.

Application fields of Fluorine lined pump

1. Chemical Industry: In the chemical industry, handling corrosive chemicals is a common task. Fluorine lined pump can ensure efficient and stable fluid transmission when transporting corrosive media such as acids and alkalis.

2. Pharmaceutical industry: The pharmaceutical industry has extremely high requirements on the cleanliness of equipment and the purity of media. The chemical stability and inertness of Fluorine lined pumps make them ideal for use in pharmaceutical processes.

3. Electronics industry: In fields such as semiconductor production, high purity requirements for liquids are extremely high. Fluorine lined pump meets the electronics industry's demand for high-purity media through its excellent corrosion resistance.

4. Environmental protection engineering: The treatment of wastewater and corrosive chemical waste liquids is an important task in environmental protection engineering, and Fluorine lined pump can play a key role in this process.

The future development trend of Fluorine lined pump

With the continuous development of chemical, pharmaceutical and other industries, Fluorine lined pump is expected to usher in wider applications in the future. At the same time, as the requirements for the durability and maintainability of industrial equipment increase, the technology and design of Fluorine lined pumps will continue to innovate to adapt to more complex and harsh industrial environments.

In the context of global sustainable development, the materials and production processes of Fluorine lined pumps will also receive more attention to ensure that they improve efficiency while reducing their impact on the environment. It is expected that Fluorine lined pump will become an important technology in the field of industrial fluid transmission, providing more reliable and efficient solutions for production in various industries.