Corrosion-resistant centrifugal pump: A game-changer in chemical processing

2024-01-22In the world of industrial water and wastewater treatment, corrosion is a constant threat to the reliability and efficiency of pumps. But a new breed of centrifugal pump is aiming to change that, introducing a level of corrosion resistance that could revolutionize the way we handle corrosive liquids.

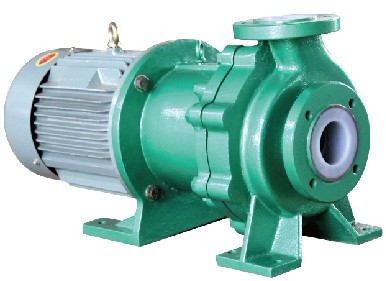

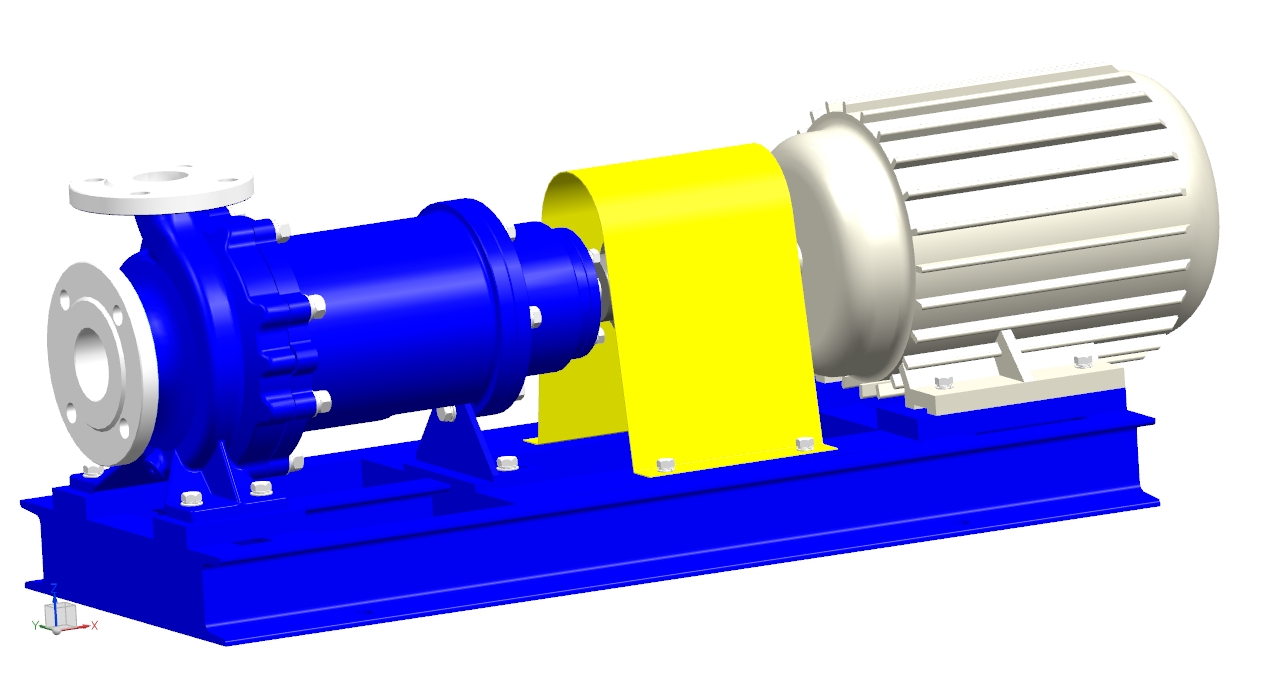

Designed with advanced materials and engineering, the corrosion-resistant centrifugal pump is built to withstand the harshest chemical environments. Its stainless steel and titanium components provide exceptional resistance to acids, alkalis, and other corrosive substances, ensuring uninterrupted operation even in the most challenging conditions.

This new pump offers a significant advantage over traditional pumps, which often require frequent maintenance and replacement due to corrosion. The corrosion-resistant design not only extends the lifespan of the pump but also reduces downtime and operational costs. It's a game-changer for industries that rely on pumps to move corrosive liquids, such as the chemical, pulp and paper, mining, and oil and gas sectors.

The corrosion-resistant centrifugal pump is not only more durable but also more efficient than traditional pumps. Its advanced design features a wider impeller for increased flow rates and reduced pressure drop, which translates into energy savings and greater productivity.

With the growing demand for corrosion-resistant equipment in various industries, the corrosion-resistant centrifugal pump is set to become a key player in the field of chemical processing. Its game-changing capabilities are already making waves in the market, paving the way for more innovative and sustainable solutions in the years to come.