Products

-

Stainless steel magnetic pump series

-

Fluorine lined magnetic pump series

-

Fluorine plastic magnetic pump series

-

Stainless steel multi-stage pump

-

Fluorine lined pump series

-

Stainless steel chemical pump series

-

Other industrial pump series

-

Fluorine plastic valve series

-

PTFE bellows, compensator

-

Pipeline

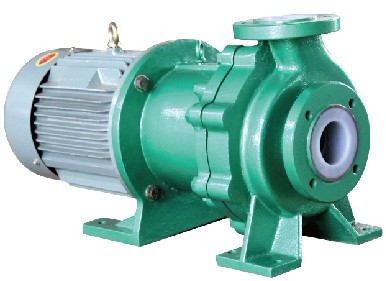

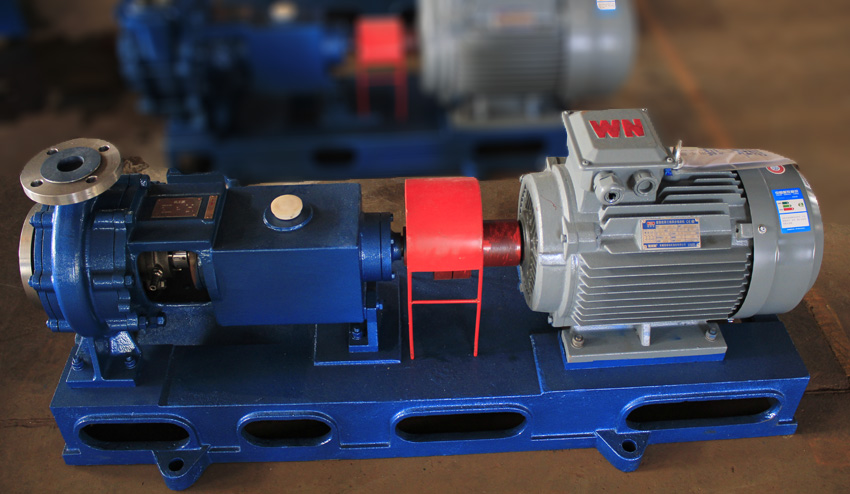

NA/NE Chemical Process Pump

Product Type: NA/NE Chemical Process Pump Main features: working temperature: - 80 ~450 C flow rate: 6m3/h~2600m3/h head: 6m~300m

Send Inquiry

Product Description

1. Product detail of NA/NE Chemical Process Pump

Product Type: NA/NE Chemical Process Pump

Main features: working temperature: - 80 ~450 C flow rate: 6m3/h~2600m3/h head: 6m~300m

2. product description of NA/NE Chemical Process Pump

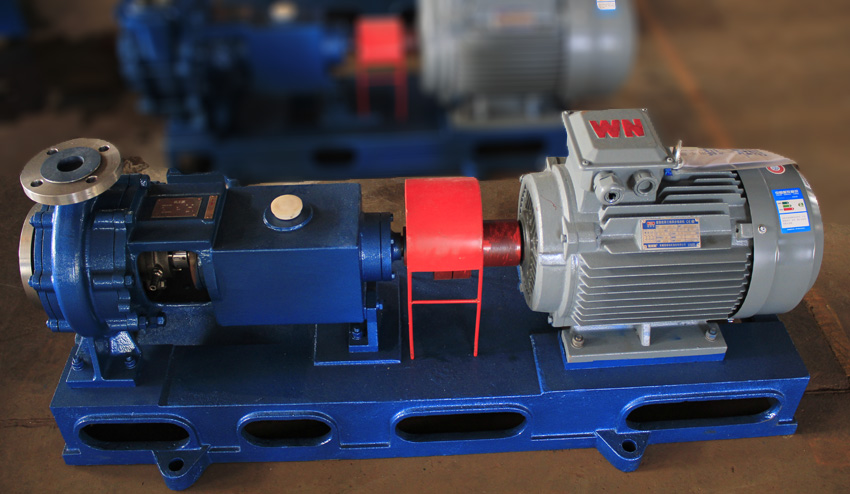

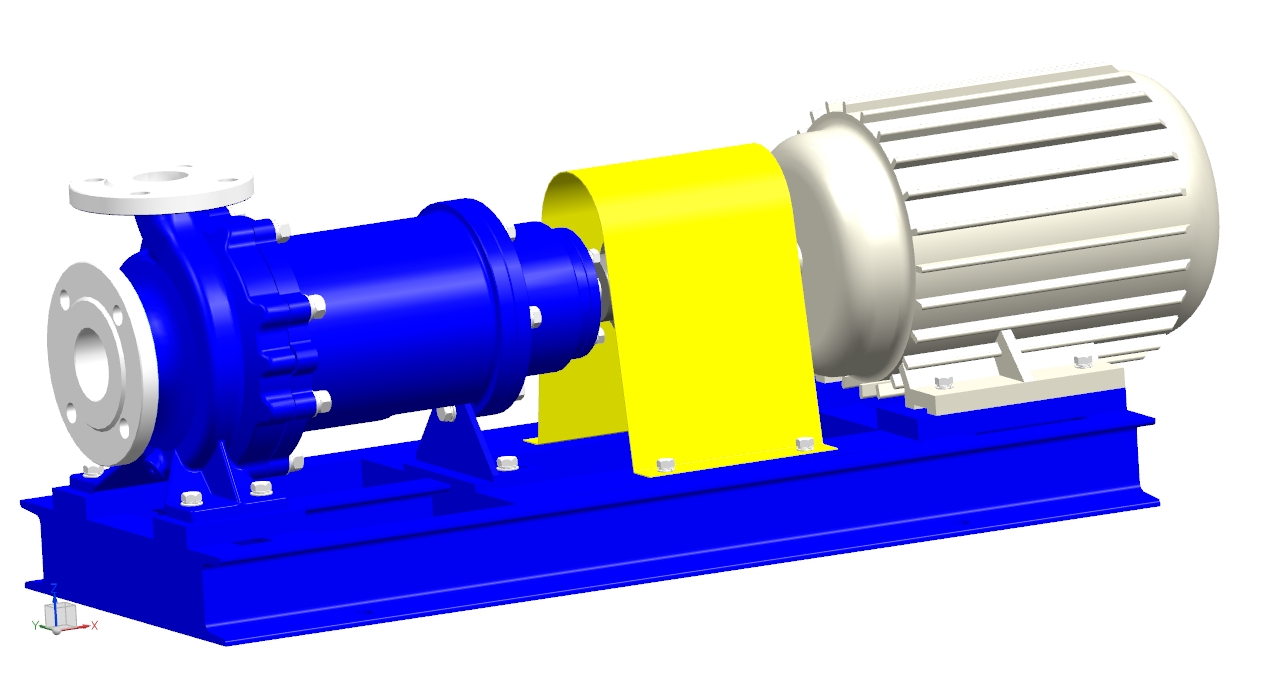

NA/NE Chemical Process Pump is improved by our company's improvement on the standard ZA and ZE petrochemical bases. The design meets the tenth edition of the AP1610, and its structure forms are horizontal, cantilever, single -level, single suction, and bottom support.

Features:

The pump body above 80 is designed with a double shell, the bottom feet are supported, and the radial force is small.

The impeller uses a replaceable mouthpiece structure to balance the axial force. The axial load is small, the vibration is small, and the operation is stable.

The sealing cavity adopts the large cavity structure, which meets the requirements of AP1682. The medium fluidity is good and the heat dissipation is fast. According to the different working conditions, single -end -end machine sealing, double -end machine city sealing, and series mechanical sealing can be adopted. Machine city sealing can be used in two forms: container and non -container.

The bearing and lubrication are designed to be designed as light pumping and heavy shafts according to different entrance pressure. The cylindrical roll is paired with the bearing and the back of the back to push the bearings, and the capacity of the load is strong.

The shaft is designed with a steel axis, the pump shaft is small and runs smoothly. The full isolation shaft sleeve completely avoids contact with the axis and the medium, reducing corrosion and improved life.

The pumping pad adopts a polytetrafluoroethylene or metal wound, which has good corrosion resistance and high -hybrid medium.

The pumping bands in the middle section of the axle structure, the maintenance does not need to be disassembled to the pipeline, which is convenient for maintenance.

3. Application of NA/NE Chemical Process Pump

Uses: It is mainly used to transport liquids with low temperature or high temperature, neutral or corrosiveness, cleaning or combined with a small amount of solid particles, which is especially suitable for chemistry, petrochemical industry, refinery, paper mills, pulp and sugar industry and special specialty Required medium.